FEATURED PROJECT: Doyon Rig 25

Doyon Rig 25

Project Overview

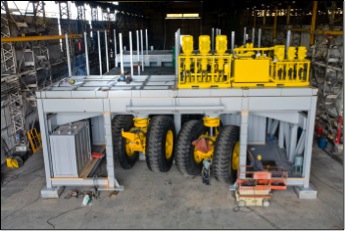

Doyon Rig 25 is a highly automated, fully integrated and mobile “work-over” drill rig capable of working efficiently in extreme arctic conditions. The rig consists of six individual units: Drill Complex, Pipe Shed, Mud Complex, Pump Complex, Power Complex, and Casing Complex. Rig 25 is designed to be trucked over marginal road conditions and floating ice bridges. This rig will be Doyon Drilling’s first AC powered, variable frequency drive (VFD) drilling rig ever built.

Thompson Metal Fab furnished over 4-million pounds of steel and aluminum fabrication and also served as the prime general contractor managing all rig-up yard activities including: mechanical, electrical, start-up, and commissioning. Rig 25 will be capable of multi-directional drilling in excess of 20,000 feet. The overall footprint is approximately 265’ x 150’ with an anticipated operational weight of 6.2 million pounds. The mast is 750 kip and has a racking capacity of 20,000 linear feet of 4” pipe.

Project Highlights

- The Rig Operates using AP Power Variable Frequency Drives

- Rig 25 is designed to operate in extreme low temperatures (-50O F)

- Mast has 750,000 pound static hook capacity

- Hydraulic moving system allows the entire rig to move fully loaded from well to well

- Rig 25 was barge transported from TMF facility to North Slope Alaska