FEATURED PROJECT: Saxon Rig Mods 147 & 169

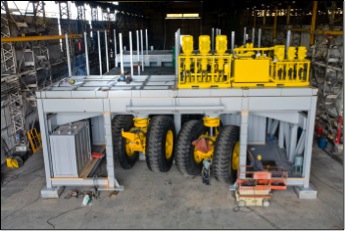

Saxon’s rig modification project included extensive retrofitting of Rigs 147 and 169 to make them suitable for Arctic conditions. This project took full advantage of our extensive rig-up yard, indoor shop space and barge slip access, and covered a broad scope of services. Both rigs saw their substructures strengthened by adding new stiffeners/cross members to the vertical legs. Additionally (and after many years of use) mast stools were replaced, BOP trolleys were cleaned up and new handrails/guardrails replaced the existing. The rigs also received an aesthetic ‘face-lift’ by adding non-skid to the drill floor and receiving touch-up painting on almost all of the existing structures.

The project was not entirely focused on retrofitting, as brand new structures were required as well, including: new catwalk roofs, mud tank and drill floor windwalls, pony subs, lifelines, and cattle chutes. Thompson provided additional value to the customer by assisting with rig-up/rig-down, field measurements, design/engineering (both through TMF and by coordinating with the Contractor’s engineers), load out, and by providing access to our pre-existing/plumbed utilities in our rig-up yard.

General Contractor

Saxon Drilling Services